To run a production system as a whole and to promote improvement kanban is used as tool. The Kanban system was implemented in 1953 in Toyota Company manufacturing process. Those signals are tracked by replenishment cycle, so that suppliers and buyers notice it. They observed that they can view a process as being a customer and proceeding process as a store. Signboards were used to give expression of shipping at the store. Kanban is part of a system where “Pull” comes from the demand. According to Taiichi Ohno , must follow strict rules to be effective, also need close monitoring of products ,so that products with defect should not be sent to subsequent process, produce exact quantity; the process should be tuned finely and rationally.

Tag: Understanding Supply Chain Management Basics

A Company’s overall success: Achieving strategic fit

Abstract: If any mismatch exists need to restructure, so that supply chain may support the competitive strategy or change the competitive strategy accordingly. Some important obstacles of achieving strategic fit are gradually increased variety of products, decreased product life cycles , increase of demanding customers as well as globalization of world economy as a whole, supply chain ownership fragmentation, […]

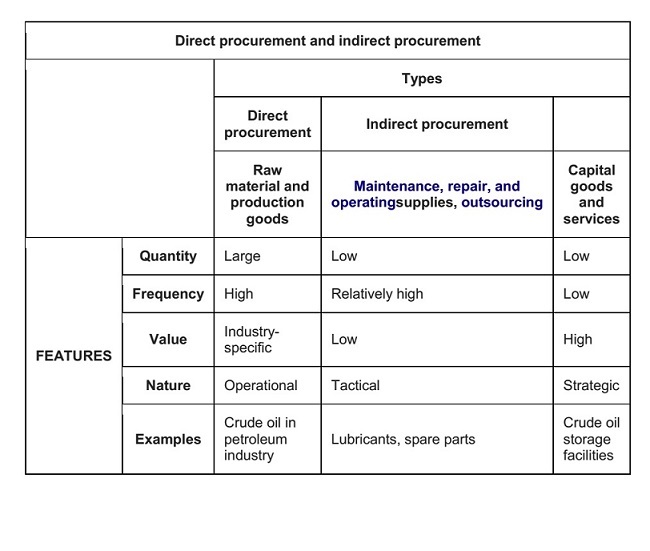

Procurement process in supply chain management: Identifying the desired focus

Abstract The materials are directly required to produce a finished product are called direct materials e.g., personal computer, hard drive etc.Direct materials are required to be available in the right place, right quantity and the right time. Direct materials are related to cost of goods, whereas an an indirect material does not determine cost directly.Indirect materials do not delay production […]

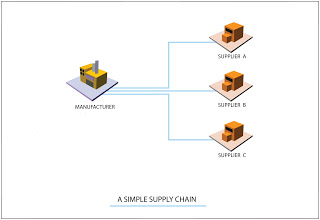

A discussion about definition of Supply Chain Management (SCM)

Abstract: To serve the customer, Supply Chain Management need to design, plan, execute, control and monitor Supply Chain activities. All stages may not be included in the supply chains. While purchasing deals with purchased goods, materials and services supply chain management discusses about inputs, conversion and outputs.For easy understanding ,we may site an example of US Textile & Apparel Supply Chain about 25,000 companies are […]

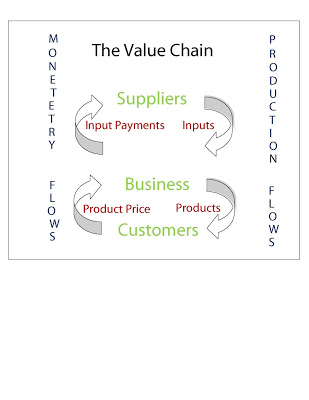

A discussion about the Value Chain (VC) concept and Business strategy

Abstract A firm value chain is a representation of various processes involved in producing goods and services starting with raw materials and ending with delivery of the finished goods to the customer.Value chain begins with new product development, which creates new product or service.The functioning of the value chain is supported by the human resources, accounting and Information technology.The value […]

A discussion to eradicate misconceptions about Green Supply Chain Management (GSCM)

Abstract GSCM aims to minimize or eliminate wastages including hazardous chemicals, emissions, energy, and solid waste along the supply chain such as product design, material resourcing, manufacturing process, and distribution of final product management business activities can pose a paramount threat to the environment in terms of carbon monoxide emissions, discarded packaging materials, scrapped toxic materials, traffic congestion and other […]