Introduction: ISCEA is the world leader in Supply Chain education , certification & different recognition programs e.g. Certified Supply Chain Manager(CSCM), Certified Supply Chain Analyst(CSCA),Post graduate diploma in Supply Chain Management (PGDSCM) etc. In this blog article will discuss about CSCM, CSCA & PGDSCM so that those who are interested in Supply Chain Education and certification will get some important […]

Search Results for: supply chain planning

IMAFS The Inventory Optimization Software

Abstract IMAFS the inventory optimization software helps knowledge gathering areas, such as, solution oriented and stock availability management, best practices in inventory management, support from experts, evolution of ROI before implementation and simplify integration, proven and rigorous implementation methodology using cloud/SAAS mode, continuous improvement with R&D, and user-friendly, integration manual parameters also. A poor delivery performance can affect consumption history.A […]

The Sustainable Development Goals (SDGs): Its Effects On Businesses and Brands

Achieving the Sustainable Development Goals (SDGs) is a critical role for businesses and brands, as it can have a big impact on their operations, strategies, branding, and stakeholder interactions. In order to meet global sustainability goals, promote innovation in goods and services as well as business models, and draw in socially conscious clientele, companies are incorporating the Sustainable Development Goals (SDGs) into their plans. ESG factors are also being considered by investors when making decisions, and businesses that support the SDGs stand to gain access to sustainable finance sources and a greater number of investments.

Goals such as “Climate Action” and “Responsible Consumption and Production” can encourage companies to streamline their supply chains, cut waste, and use more environmentally friendly production techniques. Governments are putting SDG-aligned laws into effect, and businesses need to follow them to avoid fines or reputational harm.

Facts of Transportation in a Logistical perspective: Highlights on some Bangladesh issues

Package carriers, such as DHL, FedEx, UPS, etc. usually carry letters and other small cargo weighing below 150 pounds using air, Truck, and rail to carry time-sensitive smaller packages. Companies use air cargo carriers for larger cargo and package carriers for more time-sensitive smaller cargo. A carrier takes investment decisions regarding their equipment; Shipper in contrast uses transportation to minimize total cost, while providing an appropriate level of responsiveness to the customers. The Key issues air carriers usually face include identifying the location and a number of hubs, assigning planes to routes, and maintaining a schedule of planes and crews, also available at different prices. The effectiveness of any mode of transportation is affected by the carrier as well as infrastructure and transportation policies, e.g., an airline’s goal is to maximize the daily flying time of a plane and generated revenue per trip. Supply Chains using modes of transportation, such as air, package carriers, trucking, rail, water, pipelines, intermodal, etc. The cargo moves from the factory premises to the port in a truck or multi-modal movement of truck and container on the rail. The shipper requires the movement of products from one point to another in a Supply Chain and Carrier is the party who moves the cargo. AI algorithms can optimize routes for each autonomous vehicle in real-time, based on traffic data, road conditions, and other factors. AI algorithms can mine historical and real-time traffic data to create predictive models to anticipate traffic congestion and accidents. AI will manage the optimum distance between vehicles, maintain constant communication between vehicles, and plan the formation of vehicle clusters to ensure consistent traffic flow and avoid bottlenecks. Air carriers usually carry below 500 pounds, high-value, and lightweight products.

A Lean Logistic Control System : Kanban

To run a production system as a whole and to promote improvement kanban is used as tool. The Kanban system was implemented in 1953 in Toyota Company manufacturing process. Those signals are tracked by replenishment cycle, so that suppliers and buyers notice it. They observed that they can view a process as being a customer and proceeding process as a store. Signboards were used to give expression of shipping at the store. Kanban is part of a system where “Pull” comes from the demand. According to Taiichi Ohno , must follow strict rules to be effective, also need close monitoring of products ,so that products with defect should not be sent to subsequent process, produce exact quantity; the process should be tuned finely and rationally.

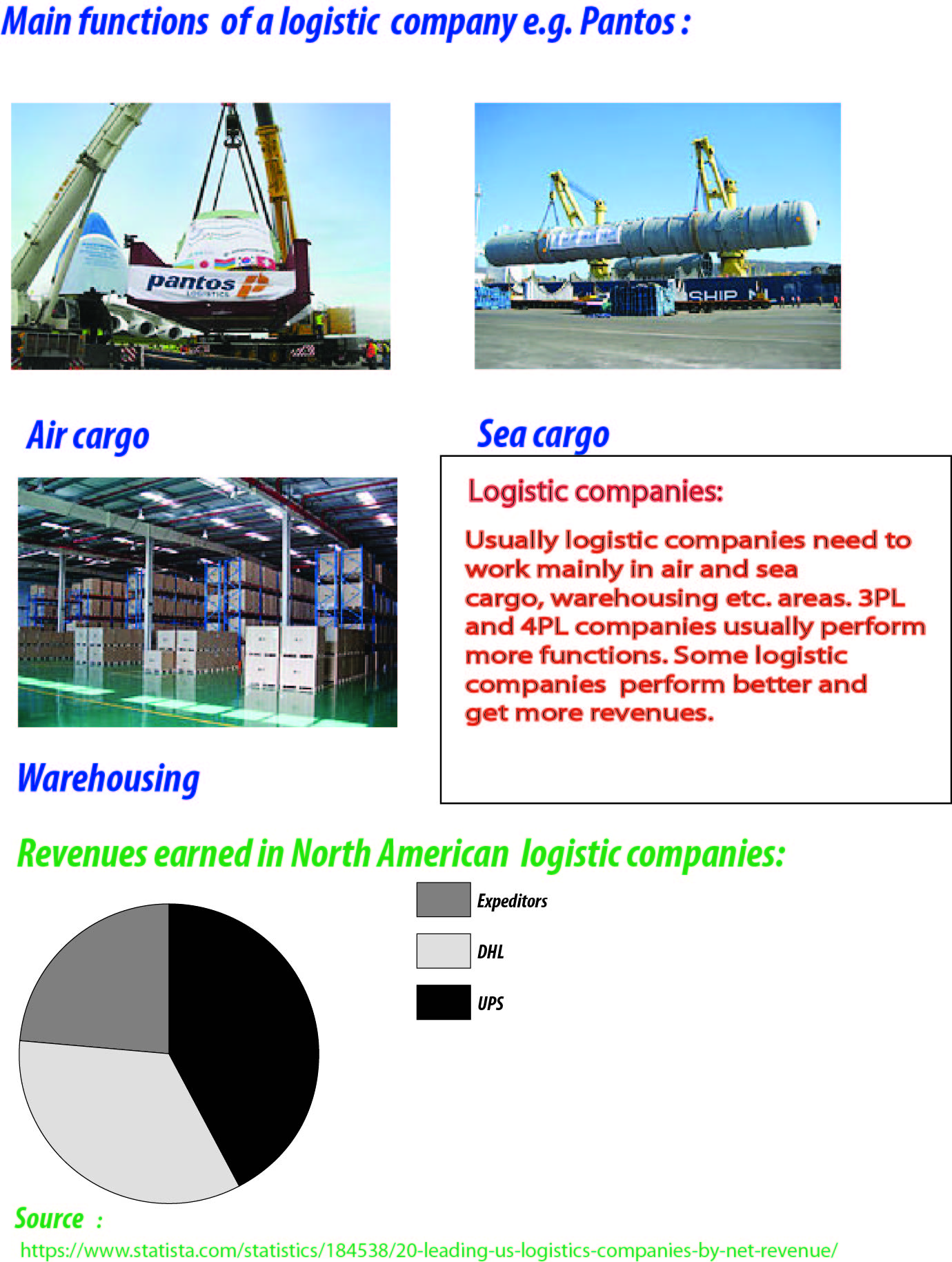

Logistics Companies and Selecting a good Logistic service provider

Abstract Procurement and logistics include market research, necessary planning, procurement decisions, logistics service provider evaluation, and order control. The main thing in advanced logistics is distribution logistics planning, which includes on-time delivery of products to the end user. Choosing a good logistics service provider is important for any company, whether it is involved in inbound logistics, outbound logistics, […]

About Logistics: A macro view point

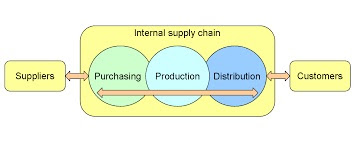

Abstract Logistical operational responsibilities include delivery of goods between suppliers, transporters and company users /customers. For instance, we can say that in the apparel supply chain of Bangladesh, we usually see that inbound goods come to manufacturing facility by the transporters and warehouse assistants receive the cargo, which is provided according to suitable lot size using suitable containers by sea or by air according to urgency of manufacturing needs to fulfill customer requests. Finished goods are loaded to containers per customer request in suitable lot sizes, so that buyer can collect and market the goods in an organized and suitable way.A macro view of logistics Logistical management function may entail some more steps, i.e., locating potential suppliers, determining their accessibility in terms of business production, and forming relationships. If the business operation is size-ably voluminous enough to outsource online operation logistics, in that case the business has to sync their platform with the third party partner. As we know, in a supply chain management, logistics and transportation are intertwined. For e-commerce companies, chat-bots can be employed to avail customers with fundamental queries such as tracking a shipment. Keywords: Supply chain management(SCM), Logistics, suppliers, transporters etc. Introduction: The term logistics refers to providing right amount of […]