Introduction The fleet functions like an orchestra, where even one malfunctioning piece of equipment can disrupt harmony and affect performance. That is why fleet managers place such great importance on developing robust maintenance schedules. Proper scheduling unlocks new levels of efficiency, keeps down fleet management costs, and improves the lifespan of crucial machinery. Here are some best practices to […]

Category: Supply Chain Management

Box Logistics, Containerization, Ports In A Global Shipping Network

Abstract Containers are the primary mode of transportation for maritime import and export flows, with 75% of total cargo carried by containers in developed areas of a global shipping network. Containerization allows for efficient distribution processes, and transshipment activities, such as warehousing, are integrated with production, distribution, and competitive supply chain strategies. Global Production Networks (GPNs) have become essential for […]

United Parcel Services Inc. : UPS Supply Chain Case Study

The American Messenger Company, founded in 1907, primarily focused on package delivery to retail stores and special delivery mail for the U.S. Post Office. In 1913, it acquired a Model T Ford as its first delivery vehicle. In 1919, the company expanded to Oakland, California, changing its name to United Parcel Service. UPS became one of the only companies in the United States to offer common carrier service, expanding to areas up to 125 miles outside the city. UPS faced direct competition with USPS and the Interstate Commerce Commission, but the common carrier service was applied in cities where UPS could use the service without the authority of the ICC and state commerce commissions. In 1953, UPS resumed air service called UPS Blue Label Air. UPS expanded its operations to serve all 48 contiguous states in the United States, Canada, and West Germany. In 1991, UPS relocated its headquarters to Sandy Springs, Georgia, and acquired Haulfast and Carryfast, rebranding them UPS Supply Chain Solutions. UPS offers international package services to over 220 countries and territories worldwide. The company faces competition from major domestic carriers like the United States Postal Service (USPS) and FedEx, as well as regional carriers like OnTrac and LSO. UPS has partnered with the US Postal Service to offer UPS Mail Innovations and “SurePost,” which use the UPS Ground network to deliver packages weighing under 10 pounds to the nearest UPS Package Center. UPS has received a “striding” environmental scorecard and received the Clean Air Excellence Award from the US Environmental Protection Agency.

How Reverse Logistics impacts on Supply Chain Management |

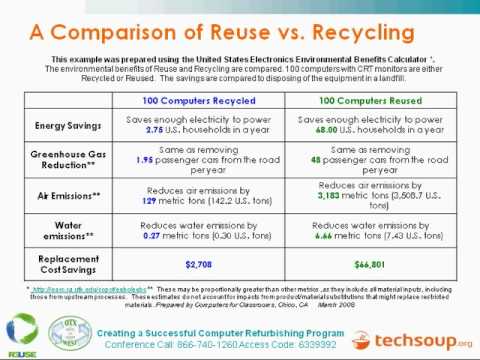

Returns avoidance, gate keeping, disposal and other supply chain issues are related with reverse logistics. The product may need to travel in reverse through the entire supply chain network to retain use of any service from the defective goods. There are closed loop supply chain networks that include returns processing and manufacturer has the intention to capture additional value and integrate all supply chain activities. Usually, asset based three 3PLs work as third party who are specialized in waste management and related activities. Reuse of manufactured and sold goods After sales service and returns management are sometimes related to the logistic companies.

IMAFS The Inventory Optimization Software

Abstract IMAFS the inventory optimization software helps knowledge gathering areas, such as, solution oriented and stock availability management, best practices in inventory management, support from experts, evolution of ROI before implementation and simplify integration, proven and rigorous implementation methodology using cloud/SAAS mode, continuous improvement with R&D, and user-friendly, integration manual parameters also. A poor delivery performance can affect consumption history.A […]

What is drop shipping: a supply chain distribution network option |

In drop-sip model, product is shipped directly from manufacturer end bypassing a retailer. Benefits of aggregation can be achieved, if the manufacturer can keep some of its inventory at the retailer end on and as needed basis. In addition, drop-shipping offers manufacturer an opportunity to postpone customization until the customer has placed order finally. Response times tend to be long, because the order has to be transmitted from retailer to the manufacturer and shipping distance are generally longer from the manufacturer’s centralizing site. Order visibility is very important in the context of manufacturer storage, because two stages in the supply chain are involved in every customer order. But a manufacturer storage network is likely to have difficulty handling returns, so that customer satisfaction may be hurt. Because, each order may involve more than one manufacturer.

Keywords: drop-shipping.

How to be a supply chain manager and what are the roles?

Abstract Supply chain managers are crucial in connecting different parts of a business’s supply chain, ensuring the value of the supply chain increases through effective management of supplier support, transportation, and distribution practices. They manage manufacturing and distribution processes, work with procurement managers, buyers, and vendors, negotiate contracts, use software to track goods, use data analytics to forecast demand, cut […]