The company was incorporated as Tesla Motors, Inc. on July 1, 2003, by Martin Eberhard and Marc Tarpenning. Eberhard verbalized he wanted to build a car manufacturer that is additionally a technology company, with its core technologies as the battery, the computer software, and the proprietary motor. Tesla Motors has become kenned for engendering well-designed and innovative electric conveyances. To assemble its cars, Tesla sources components from a range of Tesla suppliers. Some suppliers provide mundane car components; others provide electric conveyance components.

Archives

Supply Chain Management and its Drivers:

Abstract The logistical drivers are facilities, inventory, and transportation. Inventory denotes all raw materials, WIP, and finished goods in a supply chain. On the other hand, transportation involves moving inventory from point to point. Information is data about facilities, inventory, transportation, costs, prices and customers throughout the supply chain, also gives shipping options to managers. Pricing drivers determine the price […]

A brief discussion about digital supply chain management

Digital supply chain risk due to the potential for Internet of Things (IoT) security vulnerabilities, which arise when assets and machines share data via sensors and software, the digital supply chain may be exposed to danger. Stages of digital supply chain management involve planning out processes and inventory before advancing to order management.

A discussion about lack of supply chain coordination and the bullwhip effect

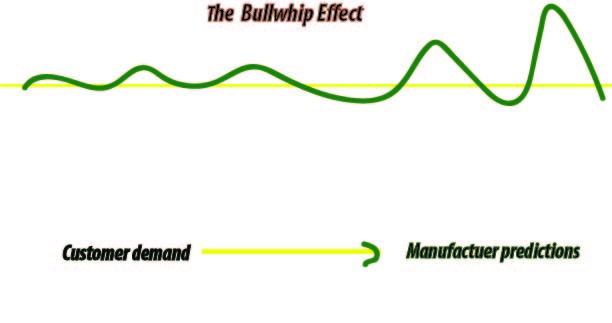

In SCM, a supply chain manager coordinates the logistics of all the aspects of the supply chain which consists of five parts: the plan or strategy, the source of raw materials and services, manufacturing, i.e., productivity and efficiency, delivery and logistics, the return system for defective and unwanted goods etc. The phenomenon that fluctuation in orders increases as one moves up the supply chain from retailers to wholesalers to manufacturers to suppliers is referred to the bullwhip effect. Managers can help achieve coordination in supply chain by aligning goals and incentives across different functions and stages of the supply chain. When supply chain moves from retailers to wholesalers to manufacturers to suppliers, the bullwhip effect occurs. It results in different stages optimizing local objectives instead of total supply chain profits. The bullwhip effect results in costs in the supply chain and decrease in levels of customer service.

H & M Supply Chain management: A case study

Hennes & Mauritz AB is a Swedish multinational clothing-retail company known for its fast-fashion clothing for men, women, teenagers, and children. As of November 2019, H&M operates in 74 countries with over 5,000 stores under the various company brands, with 126,000 full-time equivalent positions. It is the second-largest global clothing retailer, behind Spain-based Inditex (parent company of Zara). Founded by Erling Persson and run by his son Stefan Persson and Helena Helmersson, the company makes its online shopping available in 33 countries.

Supply chain: how to define the term and the process in general

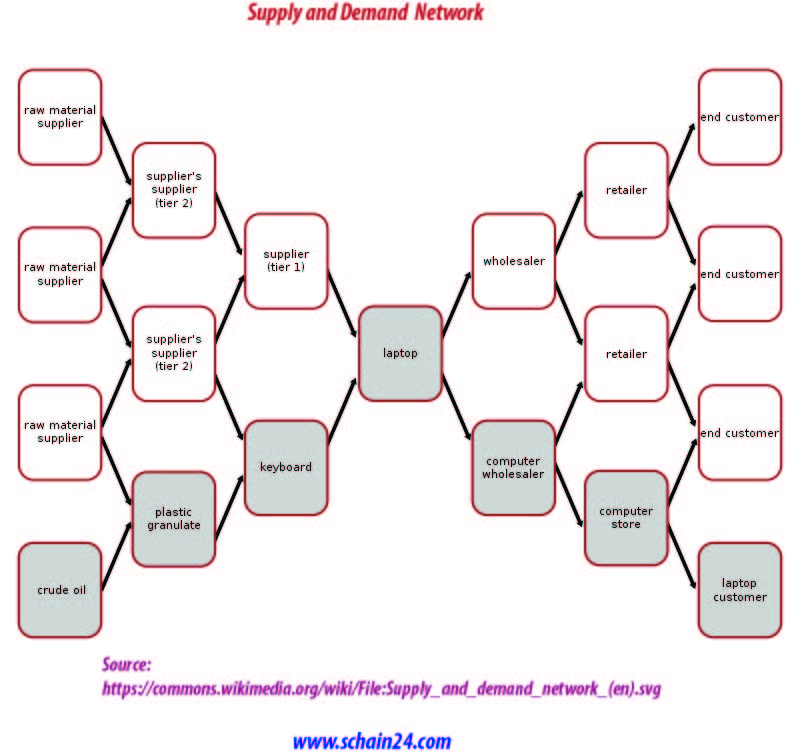

The design decisions determine the supply chain configuration and set constraints within which other supply chain drivers can be used either to decrease supply chain cost or to increase responsiveness. Mapping your supply chain denotes accumulating information about your suppliers, their own suppliers, and the people who work in your supply chain to engender an ecumenical map of your supply network. Supply-chain-management software (SCMS) is the software tools or modules used in executing supply chain transactions, managing supplier relationships and controlling associated business processes.

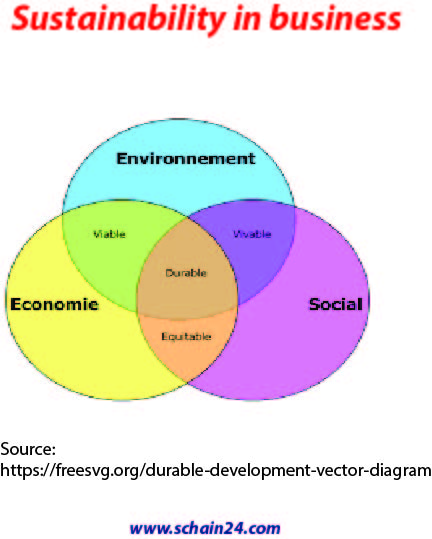

Sustainability strategy in the business world: A brief discussion

While discussing Supply Chain Management Network Design the business issue of Supply Chain Sustainability is included by high-caliber executives. The aim is different for every company such as utilizing sustainable materials in the manufacturing process, optimizing supply chains to abbreviate greenhouse gas emissions, relying on renewable energy sources to power facilities, sponsoring edification funds for youth in the local community, etc. There is a shift of paradigm from firm level to supply chain level competition and the challenge of integrating sustainability targets into corporate comportment due to growing environmental and ethical cognizance ecumenically. A sustainable supply chain is quantified by triple bottom line, which are the upstream components of the supply chain.