Abstract

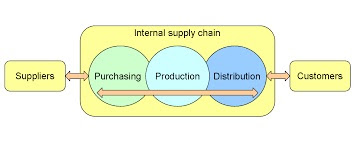

In Supply Chain Management (SCM), efficient inventory management is the result of a combination of interdependent procedures that work together to promote robustness and efficiency. Making wise decisions is necessary for inventory optimization in order to preserve equilibrium, reduce carrying costs, and avoid stockouts. Warehouse management uses sophisticated warehouse management systems and tools like SAP MM to guarantee effective product storage, retrieval, and dispatch. Shipping administration, which integrates technologies for route optimization, real-time tracking, and effective returns management, is essential for the efficient, dependable, and quick delivery of goods. Understanding and projecting customer demand is a key component of demand planning and forecasting. Our future product demand predicted by combining historical sales data, market intelligence, forecasts for raw materials, and predictive analytics. By proactively adjusting production schedules, procurement tactics, and supply plans, businesses can avoid stock-outs and guarantee that capital is not tied up.

Keywords: Role of inventory in supply chain management.

Introduction

Inventory refers to the goods and materials that a business holds for the goal of resale, production, or utilization. Inventory management is a discipline primarily about specifying the shape and placement of stocked goods. It is required at different locations within a facility or within many locations of a supply network to precede the regular and planned course of production and stock of materials. The concept of inventory, stock or work in process has been extended from manufacturing systems to service businesses and projects, by generalizing the definition to be “all work within the process of production—all work that is or has occurred prior to the completion of production”. In the context of a manufacturing production system, inventory refers to all work that has occurred—raw materials, partially finished products, finished products prior to sale and departure from the manufacturing system. In the context of services, inventory refers to all work done prior to sale, including partially process information. All these things are almost inevitable factors in supply chain management.

Effective inventory management in SCM

Effective management of inventory involves a multifaceted approach, consist of various interconnected processes. These processes work together to enhance the efficiency and resilience of inventory management within the supply chain. There are four key components that contribute to the development of a robust and adaptable inventory management strategy within Supply Chain Management. At the core of inventory management is the challenge of maintaining balance, ensuring that there is neither an excess nor a shortage of stock. Inventory optimization is centered around making informed decisions to achieve this equilibrium. This entails utilizing tools and techniques to determine the optimal levels of stock, to take into account factors such as historical sales data, seasonal fluctuations, raw material availability, and market dynamics. The goal is to minimize carrying costs while avoiding stockouts. Advanced analytics and predictive modeling play a crucial role in this process, enabling businesses to accurately forecast customer demand and make proactive procurement decisions. By leveraging these tools, companies can effectively manage their inventory levels and respond swiftly to changes in market conditions.

Warehousing effectively

The warehouse serves as the central hub for managing inventory visibility. A well-executed warehouse management strategy ensures seamless storage, retrieval, and dispatch of products. This encompasses various aspects, including the physical layout of the warehouse and the utilization of advanced inventory management software such as SAP MM or other similarly efficient solutions. These tools play a crucial role in reducing lead times, minimizing errors, and optimizing space utilization within the warehouse. Advancements in technology, such as the Internet of Things (IoT) and Artificial Intelligence (AI), have revolutionized warehouse management systems (WMS). Modern WMS solutions offer capabilities like real-time tracking, automated sorting, and robotic-assisted picking, transforming warehouses into dynamic hubs capable of responding swiftly to the evolving demands of supply chain inventory management.

Shipping administration

Once inventory is prepared for transit, the focus shifts to shipping management, which entails more than just transporting products from one location to another. It’s about achieving efficiency, reliability, and speed in the process. Critical elements involve selecting the most suitable shipping methods, maintaining positive relationships with carriers, and guaranteeing punctual and accurate deliveries. In today’s landscape, where customers expect rapid shipping and seamless tracking, adept shipping management is indispensable for staying ahead in the market. Incorporating technologies like route optimization, real-time tracking, and streamlined returns management can substantially elevate this aspect of Supply Chain Management.

Demand planning and forecasting

Understanding and accurately predicting customer demand forms the foundation of efficient inventory management. Demand planning integrates historical sales data, market insights, forecasts of raw materials, and predictive analytics to anticipate future product demand. This proactive approach empowers businesses to adapt their production schedules, procurement strategies, and supply plans accordingly. Not only does it prevent stock-outs, but it also prevents unnecessary capital from being tied up in excessive inventory. In today’s volatile market, characterized by rapidly changing trends, agile demand planning is indispensable for the success of Supply Chain Management. The integration of these components is crucial in developing an inventory management system that is both resilient and adaptable. As the landscape of the supply chain continues to develop, mastering these aspects ensures that businesses remain at the forefront, optimizing their operations, and meeting customer demands with precision.

Some other terms help to understand inventory’s role in supply chain management:

Stock Keeping Unit (SKU) SKUs are clear, internal identification numbers assigned to each of the products and their variants. SKUs can be any combination of letters and numbers chosen, just as long as the system is consistent and used for all the products in the inventory. An SKU code may also refer to as product code, barcode, part number or MPN (Manufacturer’s Part Number).

“New old stock” (sometimes abbreviated NOS) is a term used in business to refer to merchandise being offered for sale that was manufactured long ago, but used. Such merchandise may not produce anymore, and the new old stock may represent the only market source of a particular item at the present time.

ABC analysis (also known as Pareto analysis) is a method of classifying inventory items based on their contribution to total sales revenue. This can use to prioritize inventory management efforts and ensure that businesses are focusing on the most important items.

Buffer/safety stock: Safety stock is the additional inventory that a company keeps on hand to mitigate the risk of stock-outs or delays in the supply chain. It is the extra stock that is kept in reserve above and beyond the regular inventory levels. The purpose of safety stock is to provide a buffer against fluctuations in demand or supply that could otherwise result in stock-outs.

Reorder level: Reorder level refers to the point when a company place an order to re-fill the stocks. Reorder point depends on the inventory policy of a company. Some companies place orders when the inventory level is lower than a certain quantity. Some companies place orders periodically.

Cycle stock: Used in batch processes, cycle stock is available inventory, excluding buffer stock.

De-coupling: Buffer stock held between the machines in a single process, which serves as a buffer for the next one allowing a smooth flow of work instead of waiting the previous or next machine in the same process.

Anticipation stock: Building up extra stock for periods of increased demand—e.g., ice cream for summer.

Pipeline stock: Goods still in transit or in the process of distribution; e.g., they have left the factory but not arrived at the customer yet. Often calculated as: Average Daily / Weekly usage quantity X Lead time in days + Safety stock.

Raw materials: Materials and components scheduled for making a product.

Work in process (WIP): Materials and components that have begun their transformation to finished goods. We use in a process of manufacture and as such, these are neither raw material nor finished goods.

Finished goods: Goods ready for sale to customers.

Goods for resale: Returned goods that are salable.

Stocks in transit: The materials which are not at the seller’s location or buyers’ location but in between are “stocks in transit”. Or we could say, the stocks which left the seller’s plant but have not reached the buyer, and are in transit.

Conclusion

Inventory has a very important role in supply chain management and warehousing. It is not possible to serve the customer properly without proper inventory management and warehousing.

Reference:

- RHODES, CLAIRE. (2023). “4 benefits of inventory management in supply chain”. https://www.linnworks.com/blog/inventory-management-in-supply-chain/.

- “Production and Operations Management: Manufacturing and Services”, R.B. Chase, N.J. Aquiline and F.R. Jacobs, Eighth Edition, 1998, pp 582-583

- https://youtu.be/dALkapy4anM?si=W3dexErcdM4n1Wby

- https://rumble.com/v4t0ipz-how-inventory-impacts-your-supply-chain-.html

- https://youtube.com/shorts/yTmbxGiATWc?si=4ygambJdP6OhVrx4