Abstract

Containers are the primary mode of transportation for maritime import and export flows, with 75% of total cargo carried by containers in developed areas of a global shipping network. Containerization allows for efficient distribution processes, and transshipment activities, such as warehousing, are integrated with production, distribution, and competitive supply chain strategies. Global Production Networks (GPNs) have become essential for manufacturers to consider global logistic strategies, governance, transportation, and value-added services. Liner services, such as Maersk Line and MSC, can integrate trade routes, but schedule integrity often compromised because of port terminal congestion. Re-positioning issues of empty containers are a complex issue related to global freight distribution, influenced by trade imbalance, container manufacturing costs, leasing costs, and usage preferences. Port hinterland relations are crucial for port development, as they enable access to cargo bases and create regional load center networks and logistic poles. Environmental constraints and local opposition to port development also play a role in port development.

Keywords: Global shipping network.

Introduction

Cycle Inventory is the average inventory because of production, purchase and also shipping, and containerization in lot sizes that are usually larger than those demanded by customers. Where containers are the primary mode of transportation for maritime import and export flows, with 75% of total cargo carried by containers in developed areas of a global shipping network. Ports are maritime facilities with wharves or loading areas. They handle cargo, passengers, and provide entry for immigrants and soldiers. Ports play a crucial role in the global economy, with 70% of global merchandise trade passing through them. Many port cities have experienced multicultural changes throughout their histories. Asia has seen the greatest growth in port development. Environmental impact includes water quality issues and vulnerability to climate change. Global ports are working on improving coastal management practices and integrating climate change adaptation practices.

Containerization

Maritime import and export flows of general cargo are shipped by containers in most developed areas of this world. So far, 75% of the total cargo is carried by containers. Very big container career ships, such as cf. Emma Maersk: LOA 397m, beam 56.40 has over than 10,000 TEU capacity(official capacity 11,000TEU), but not technically too high range from the initial vessels. Economies of scale are followed as far as technically okay. Containerization makes the distribution process in a large degree possible in the global shipping network.

Transshipment of containers

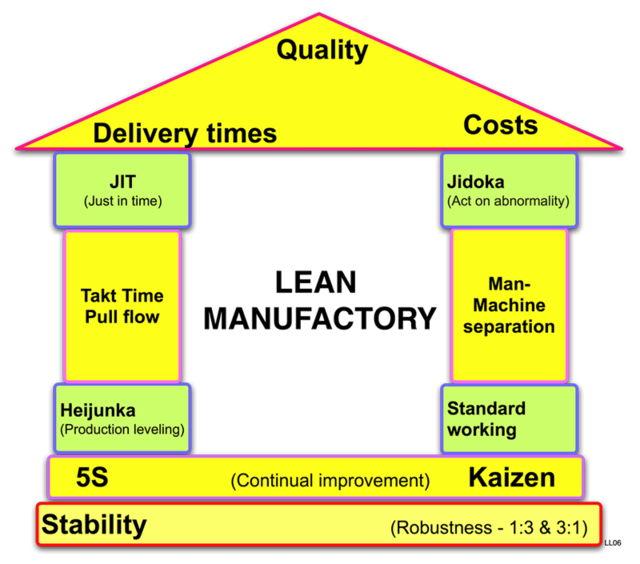

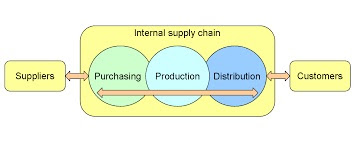

The concept of transshipment includes in a large sense includes activities take place when the freight is not in circulation, such as warehousing as distribution centers in a global shipping network. These are based on the principle of ‘Just in Time’, while integrating the velocity of the freight with production, distribution and competitive supply chain strategies.

Containerization and Global Production

The Shipping and Liner Services

Schedule reliability issue

Re-positioning issues

The re-position issues of empty containers are one of the most complex problems, which are related to global freight distribution. Trade imbalance, container manufacturing costs, leasing costs, and usage preferences are the major reasons for this problem.

The Regions and ports

Port hinterland relations are important in port development. Access to cargo bases of the port in the hinterland developed in this way. An important driver for the creation of regional load center networks and logistic poles are the related requirements of global supply chains. Environmental constraints and local opposition to port development are also important issues for developing the port region.

Environmental issues in ports

Ports and their operation contribute to environmental issues, including sediment contamination, spills from ships, and susceptibility to human-caused climate change. Each year, 100 million cubic meters of marine sediment dredged to improve waterways around ports, disturbing local ecosystems and releasing pollutants captured in the sediments.Invasive species usually spread through bilge water and ship hulls, with over 7000 invasive species estimated to be transported daily around the world. These species can have direct or indirect interactions with native sea life, impacting ecosystems.Ports contribute to increased air pollution because of ship and land transportation, leading to higher exhaust emissions and related health effects on local communities.Water quality around ports is lower due to direct and indirect pollution from shipping, as well as challenges caused by the port’s community, such as trash washing into the ocean.Sewage, oil, and chemical leaks from shipping vessels can contaminate local water, causing pollution and other adverse effects.Ports and their infrastructure are vulnerable to climate change and sea level rise, leading to subsidence, coastal flooding, and other direct pressures on the port.Various initiatives, such as SIMPYC, the World Ports Climate Initiative, the African Green Port Initiative, Eco ports, and Green Marine, aim to decrease negative environmental effects of ports. The World Port Sustainability Program identifies the Sustainable Development Goals as potential ways of addressing port sustainability.

Conclusion

Freight transportation is a very costly and volatile component of the Supply Chain and logistic operations. Managers and governments have to deal with delays in the transport system, rising oil prices, global supply chain security issues, labor and equipment shortages, and trade imbalances. An intelligent port leverages various technologies, such as artificial intelligence (AI) and the Internet of Things (IoT), to enhance its efficiency in managing cargo.As part of the process of greater automation to help generate the operating flow that helps the port function properly, smart ports typically use cloud-based software. Majority of ports worldwide currently have some embedded technology, if not complete leadership. Nonetheless, the quantity of intelligent ports has progressively grown because of international government initiatives and the rapid expansion of maritime trade. According to a report by business intelligence firm Visiongain, the smart ports market expected to generate $1.5 billion in revenue by 2019.

Further Reading:

- Asariotis, Regina; Benamara, Hassiba; Mohos-Naray, Viktoria (December 2017). Port Industry Survey on Climate Change Impacts and Adaptation(PDF) (Report). UN Conference on Trade and Development. Archived(PDF) from the original on 2020-11-25.

- “Maritime ports freight and passenger statistics” (PDF). Eurostat. Archived (PDF) from the original on 2017-07-22. Retrieved 18 June 2020.

- “‘Smart Ports Market spending will reach $1.5bn in 2019’, says Visiongain”. Visiongain (Press release). 2019-09-05. Retrieved 2019-09-09.

- https://youtu.be/iy49a8zLUNU?si=_FFuJUohzbxCpfvM

- https://rumble.com/v56wg85-the-vital-role-of-ports-and-containerization-in-global-trade.html

thats a great blog i learned a lot from it

As a new participant in your blog, I just want to say that all the information you have given here is awesome. Thank you military pelican cases

Hey Place your Freight Request on http://ShippingExchange.com for FreightQuotes in your budget(Lowest Price Freight Quotes)