Abstract:

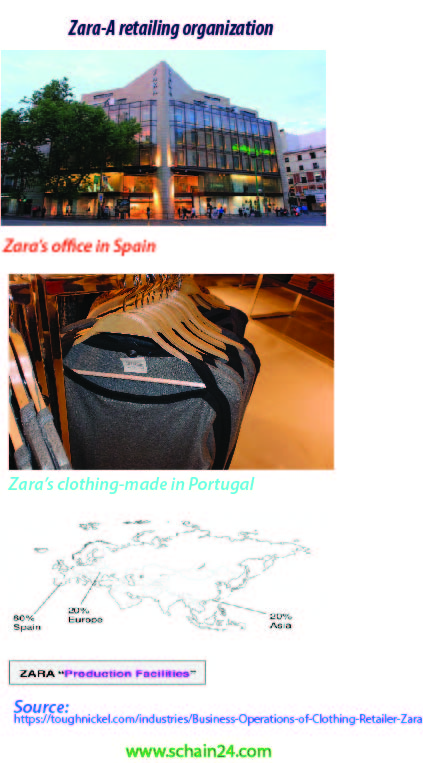

The retailing organization Zara has suppliers from about 50 countries. Zara is called “Fast fashion” in a segment of the market. Following things in Zara’s ICT try to seamlessly coordinate between organizations and enhance supply chain integration. The organization’s technology improves operational responsiveness to customers, at the same time reduces cost. her main strategy is to answer quickly to consumer demand and anticipate consumer trends through IT and human resources. Zara continues to update information based on checking with store managers using PDA and updating customers’ responses.

Keywords: Zara, A retailing organization, fast fashion, ICT, etc.

Introduction:

Zara is a good example of a retail organization, which needs to purchase materials. For this, they need to create a good supply chain model. They purchase raw materials mostly from Spain, Greece, and Italy. Therefore, they can purchase better quality raw materials at the earliest. Inditex is the biggest branch of this retailing organization. The ICT of this organization is helpful.

Suppliers:

The retailing organization Zara has suppliers from about 50 countries. Some are nothing but handling plants. A wide variety of assortments of things is enabled for customers in this way. Most of their creations are enabled by suppliers around Spain. They are bound to comply with Zara’s implicit rules for its obligations to customers. Working as a pristine player in fashion retail like Zara provide some power among suppliers, like price leverage, and frequent quality audit to evade issues such as children worker, refugee worker, or other ethnic issue. When Zara works with Europe suppliers for paramount raw material as tissue, it works with Chinese suppliers’ rudiments products such as buttons and zippers. Suppliers are a very consequential link of the supply chain, and to have suppliers that are far away may cause some issues in terms of logistic-like issues.

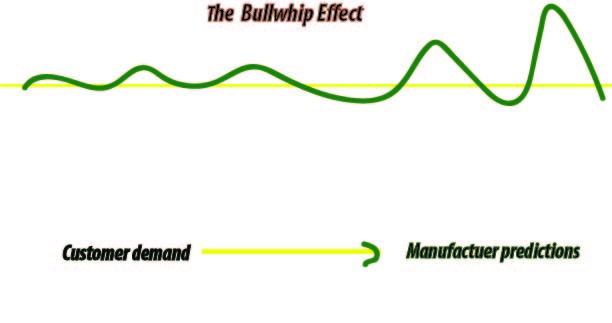

Fast fashion:

Zara is called “Fast fashion” in a segment of the market. Make ready-to-wear emphasizes the transition between couture and catwalk fashion. Therefore, the strategic focus becomes speed and price. The faster they move, they will get the fast move advantage and the cheaper they can do it their profit margin would be greater.

Trinity of fashion:

The designers, textile manufacturers, and laborers are all in one location, not more than 20 minutes distance. For this, they need an urgent amount of infrastructural investment and solid management. They implement the

“Just-in-time” formula this way.

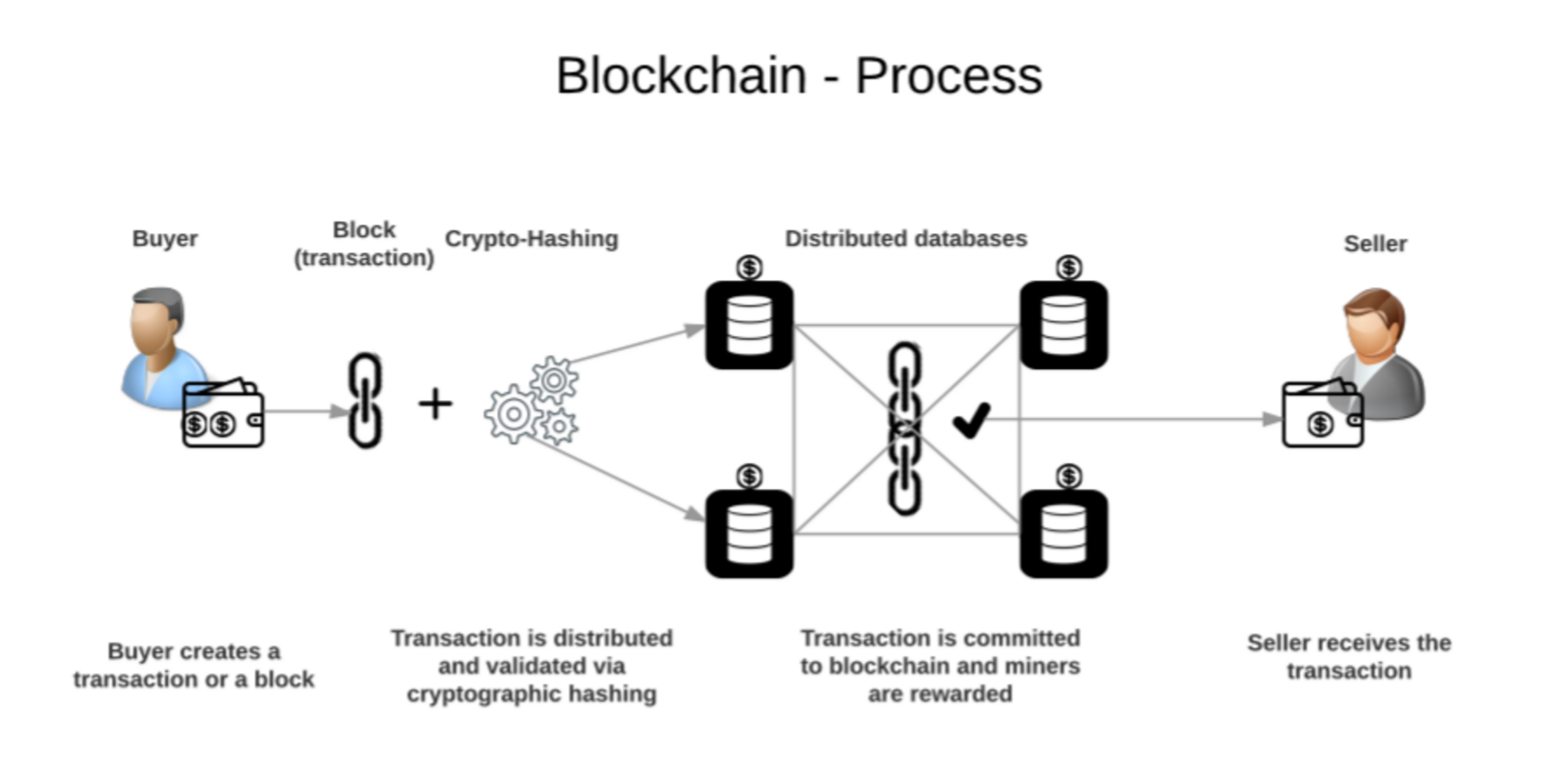

Zara’s ICT:

Following things in Zara’s ICT try to seamlessly coordinate between organizations and enhance supply chain integration. Inter-organization ICT and supply chain performance refers to the data technology and linking and matching organization. ICT is greatly emphasized in the current supply chain literature. It is important also to understand the relationship between selective information and the executive system. It also enhances inter-organization practices between buyers and vendors.

Purchasing cost analysis:

Zara’s technology improves operational responsiveness to customers, at the same time reduces cost. Zara’s main strategy is to answer quickly to consumer demand and anticipate consumer trends through IT and human resources. Its supply chain relies on backward integration and controlling manufacturing and distribution on the basis of consumer response. Its simple and effective IT and high-tech DC help in this purpose. It optimizes cost in terms of basic production items and also optimizes time. Zara continues to update information based on checking with store managers using PDA and updating customers’ responses. Store computers give them Point of sale information also DC mobile tracking area and barcode garment keep systems. After orders were approved warehouses issued lists of delivery to the stores. Designers bridge merchandisers and back-end production to develop the right products within its season to meet consumer demand. The DC is not only a store, but also a place of merchandise.

Zara took steps in favor of non-toxic clothing

Greenpeace published its “Toxic Threads: the big fashion stitch-up” report in November 2012 as part of its Detox Campaign identifying companies that use toxic substances in their manufacturing processes. Within a few days after the report was published, Zara committed to eradicating all releases of hazardous chemicals throughout its entire supply chain and products by 2020. Zara became the greatest retailer in the world to raise awareness for the Detox Campaign and switched to a fully toxic-free production.

Zara’s 2025 goal

Fast fashion retailer Zara is going green. All of the cotton, linen, and polyester used by Zara will be organic, sustainable, or recycled by 2025, parent company Inditex announced this week. Zara’s business strategy relies on four key pillars: Flexibility of supply. Instant absorption of market demand. Response speed.

Conclusion:

Zara’s operational systems, suppliers, and ICT are jointly responsible for the most successful retailing organization. Most fashion houses maintain their Design and manufacturing facilities in completely different places. As for example, GAP has stores in the USA, but its manufacturing facilities are mainly in Indonesia, Vietnam, China, etc. They have to give slow shipping and sailing time also.

References:

2.https://www.inditex.com/sustainability/environment/logistics. https://www.forbes.com/sites/kevinomarah/2016/03/09/zara-uses-supply-chain-towin-again/#7f1bc5ca1256

3.https://www.forbes.com/sites/kevinomarah/2016/03/09/zara-uses-supply-chain-towin-again/#7f1bc5ca1256

4. http://jeremybonioni.strikingly.com/blog/business-case-purchasing-strategy-of-zara

5. https://toughnickel.com/industries/Business-Operations-of-Clothing-Retailer-Zara

6. “People! Zara commits to go toxic-free”. Greenpeace.org. 29 November 2012.

7,https://edition.cnn.com/2019/07/19/business/zara-sustainable-fashion-trnd/index.html#

8.https://youtu.be/J4a3LVOy0Is

9.https://rumble.com/v32nhc2-zaras-supply-chain-a-case-study.html